Table of Contents

The aerospace industry is a highly specialized field that demands the highest levels of precision, quality, and safety. To meet these demands, aerospace manufacturers rely on a wide array of specialized factory equipment and supplies. This article will discuss some of the most essential equipment and supplies used in aerospace manufacturing.

Precision Machining Equipment

Precision machining is a critical process in aerospace manufacturing, as it involves shaping and contouring complex parts from various materials such as aluminum, titanium, and composites. Several essential pieces of equipment contribute to this process:

- CNC Milling Machines: These computer-controlled machines utilize rotating cutters to shape and contour metal parts with extreme precision.

- CNC Turning Centers: These machines rotate the workpiece while a cutting tool removes material, enabling the production of cylindrical and tapered components.

- EDM (Electrical Discharge Machining) Machines: These machines use electrical sparks to erode material, allowing for the creation of complex shapes and intricate geometries.

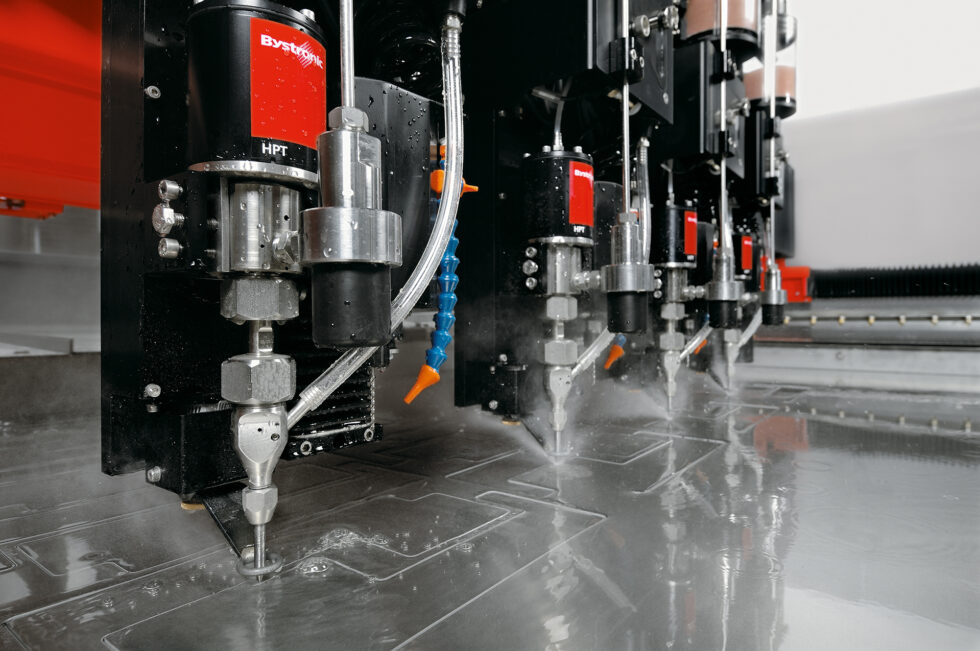

- Waterjet Cutting Machines: These machines utilize high-pressure water streams to cut through a variety of materials, including metals, composites, and plastics.

Assembly and Structural Bonding Equipment

Aerospace structures often involve the assembly of multiple components, often requiring specialized bonding techniques:

- Assembly Tools: These tools include precision jigs, fixtures, and clamps that ensure accurate alignment and secure positioning of components during assembly.

- Adhesive Dispensing Systems: These systems control the application of adhesives, ensuring consistent and precise bonding between components.

- Autoclaves: These pressurized chambers provide a controlled environment for curing advanced composite materials, ensuring their structural integrity.

Testing and Inspection Equipment

Aerospace components undergo rigorous testing to guarantee their performance and safety:

- Ultrasonic Testing (UT): UT uses sound waves to detect internal defects in materials, ensuring the integrity of critical components.

- Radiographic Testing (RT): RT employs X-rays to visualize internal structures, revealing defects such as cracks or voids.

- Coordinate Measuring Machines (CMMs): These machines measure the dimensions and geometries of components with extreme accuracy, ensuring they meet precise specifications.

Surface Preparation and Finishing Equipment

Aerospace components often require specialized surface treatments to enhance their properties:

- Cleaning and Deburring Systems: These systems remove contaminants and smooth rough edges, ensuring a clean and uniform surface for subsequent processes.

- Anodizing and Plating: These processes create protective layers on metal surfaces, enhancing corrosion resistance and wear properties.

- Surface Grinding and Polishing: These techniques achieve extremely smooth and precise surfaces, critical for optical components and other sensitive applications.

Quality Control and Data Management Equipment

Aerospace manufacturers employ sophisticated quality control systems to ensure the consistent production of high-quality components:

- Quality Control Software: This software manages inspection data, tracks component traceability, and facilitates quality assurance audits.

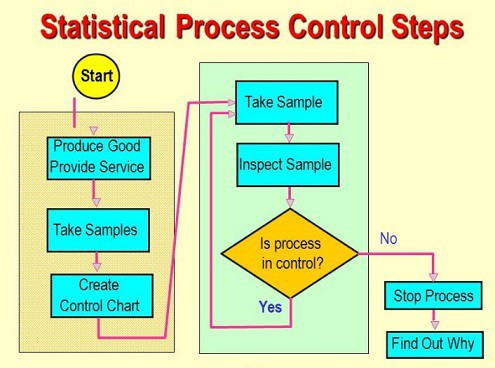

- Statistical Process Control (SPC) Tools: SPC techniques monitor production processes, identifying potential variations and preventing defects.

- Data Analytics Platforms: These platforms analyze large datasets to identify trends, predict potential issues, and optimize manufacturing processes.

Essential Supplies for Aerospace Manufacturing

In addition to specialized equipment, aerospace manufacturers rely on a wide range of essential supplies to support their production processes:

- Cutting Fluids and Lubricants: These fluids and lubricants are used to cool and protect cutting tools during machining operations.

- Adhesives and Sealants: These materials are used to bond components together and prevent leaks in fluid systems.

- Cleaning and Degreasing Agents: These chemicals are used to remove contaminants from components prior to assembly or finishing processes.

- Protective Coatings: These coatings are applied to components to protect them from corrosion, wear, and other environmental factors.

- Testing and Inspection Consumables: These materials include dyes, penetrants, and developers used in non-destructive testing (NDT) procedures.

Conclusion

Factory equipment and supplies play a critical role in aerospace manufacturing, enabling the production of high-precision, reliable components that power aircraft and spacecraft. These specialized tools and materials play a vital part in shaping the future of aerospace innovation and ensuring the continued safety, efficiency, and performance of aviation technology.

As the aerospace industry continues to evolve, driven by advancements in materials, technologies, and manufacturing processes, the demand for innovative and sophisticated factory equipment and supplies will only grow. Manufacturers will constantly seek ways to enhance precision, reduce production time, and improve the overall quality of their products.

In addition to the equipment and supplies discussed in this article, several emerging technologies hold promise for the future of aerospace manufacturing. These include:

- Additive manufacturing (AM), also known as 3D printing, is revolutionizing aerospace manufacturing, enabling the production of complex geometries and reducing material waste. AM is expected to play an increasingly important role in the production of custom-made aerospace components.

- Artificial intelligence (AI) and machine learning (ML) are being integrated into manufacturing processes to optimize operations, predict potential failures, and enhance decision-making. AI and ML are expected to transform aerospace manufacturing by enabling predictive maintenance, real-time process control, and data-driven optimization.

- Internet of Things (IoT) technology is connecting factory equipment and systems, enabling real-time data collection, analysis, and control. IoT is expected to enhance supply chain management, improve production efficiency, and facilitate predictive maintenance.

As these technologies mature and integrate into aerospace manufacturing, the industry is poised for continued advancements in precision, efficiency, and innovation. The future of aerospace manufacturing will be characterized by a seamless blend of cutting-edge technology, advanced materials, and specialized equipment, all working together to produce the exceptional products that define the aerospace industry.

0 Comments