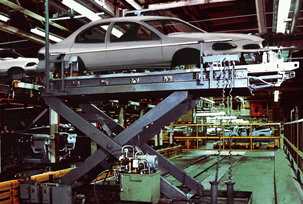

Tork Heavy Duty Scissor Lift Table

Tork Heavy Duty Scissor Lift Table Features:

- All scissors rollers are captured within structural steel channels to provide excellent load stability

- High impact, spiral wound bearings at every pivot point provide maintenance-free, rugged resistance to abrasion, impact, and uneven loads.

- Structural cross-members at every pinned joint in the scissors assembly minimizes leg deflection due to twisting or spreading under high/uneven loading.

- All hydraulic cylinders contain two-piece, self-aligning piston rods that transmit minimal side forces to the cylinder hinges/pins, significantly reducing wear.

- Structural steel channels in all top and lower frames provide additional rigidity and resistance to twisting/bending of the lift under load.

- Solid steel legs and added stiffeners provide overall stability and straight, repeatable roller tracking as the lift raises and lowers.

- Joints, the most critical wear points in the lift, feature chrome-plated, 100,000 psi, ultimate-strength pins for premium load strength and long life.

- Minimum 1/4-inch-thick steel-reinforced platform minimizes deck deflection, maximizes load stability, and greatly extends the life of the platform deck.

Maintenance and Warranty

- IML offers an industry-best 2 year warranty on all parts as a promise that you've purchased the industry's most reliable scissor lift.

- One-piece, removable center axle pin adds rigidity to the scissors mechanism and allows easy inspection and maintenance of the axle pin - a task that is virtually impossible on competing brands.

- On-board maintenance devices enable maintenance crews to safely and effectively block open the scissors during inspection and routine maintenance.

- Sturdy, semi-transparent polyurethane oil reservoir provides an easily visible method of checking fluid levels and eliminates oil contamination due to rust.

- Low pressure hydraulic circuit extends the life of all hydraulic components and puts less stress on the electric motor.

- Double wire braided Parker hydraulic hoses resist wear, abrasion, and leaks.

Simplicity

- Standard controls are prewired and internal power unit is onboard. Installation simply includes lagging the unit to the ground and connecting to electricity.

Safety

- Hydraulic velocity fuses completely stop lifts in the unlikely event of uncontrolled descent due to sudden hose rupture.

- Minimum 3:1 structural factor of safety makes these lifts the most structurally sound lift in the industry.

- Compliance with recognized standards:

- ANSI MH29.1 - Safety Requirements for Industrial Scissor Lifts

- NFPA 70 - National Electric Code

- ASTM - A36 - Structural Steel Standard

- ANSI Z535 - Safety Labeling Requirements

- AWS D.1 - Welding Standards

- Applicable portions of OSHA 29CFR1910 - General workplace safety

Tork Heavy Duty Scissor Lift Table Dimensions:

| Model | Travel (inches) | Capacity (lbs#) | Lowered Height (inches) | Raised Height (inches) | Base Frame Width | Base Frame Length | Maximum Platform Width | Maximum Platform Length | Shipping Weight Approx# (lbs#) |

| T1-024-022 | 24 | 2200 | 6 | 30 | 24 | 36 | 36 | 48 | 325 |

| T1-036-015 | 36 | 1500 | 6 | 42 | 24 | 48 | 36 | 60 | 450 |

| T1-036-022 | 36 | 2200 | 6.5 | 42.5 | 23.5 | 47 | 48 | 72 | 525 |

| T1-036-044 | 36 | 4400 | 6.5 | 42.5 | 23.5 | 47 | 48 | 72 | 600 |

| T1-036-060 | 36 | 6000 | 7 | 43 | 23.5 | 47 | 44 | 68 | 650 |

| T1-036-080 | 36 | 8000 | 12 | 48 | 45 | 59.5 | 66 | 80 | 2150 |

| T1-036-100 | 36 | 10000 | 14 | 50 | 35 | 62.5 | 54 | 82 | 2600 |

| T1-036-120 | 36 | 12000 | 14 | 50 | 35 | 62.5 | 54 | 82 | 2800 |

| T1-036-160 | 36 | 16000 | 16 | 52 | 35 | 70 | 54 | 92 | 3000 |

| T1-036-300 | 36 | 30000 | 17.375 | 53.375 | 36 | 80 | 56 | 100 | 3200 |

| T1-048-020 | 48 | 2000 | 8 | 56 | 28 | 65.5 | 48 | 86 | 1200 |

| T1-048-040 | 48 | 4000 | 8 | 56 | 28 | 65.5 | 48 | 86 | 1250 |

| T1-048-060 | 48 | 6000 | 9 | 57 | 28 | 65.5 | 48 | 86 | 1350 |

| T1-048-080 | 48 | 8000 | 13.25 | 61.25 | 30 | 77 | 50 | 98 | 3200 |

| T1-048-100 | 48 | 10000 | 15 | 63 | 40 | 80 | 60 | 100 | 3600 |

| T1-048-120 | 48 | 12000 | 16 | 64 | 40 | 80 | 60 | 100 | 3600 |

| T1-048-160 | 48 | 16000 | 16 | 64 | 40 | 80 | 60 | 100 | 3600 |

| T1-048-200 | 48 | 20000 | 16 | 64 | 40 | 80 | 60 | 100 | 4400 |

| T1-048-300 | 48 | 30000 | 18 | 66 | 44 | 84 | 62 | 102 | 6000 |

| T1-060-025 | 60 | 2500 | 9.75 | 69.75 | 48.5 | 95.75 | 68 | 116 | 2100 |

| T1-060-040 | 60 | 4000 | 9.75 | 69.75 | 47 | 82 | 68 | 102 | 2100 |

| T1-060-060 | 60 | 6000 | 11.75 | 71.75 | 54 | 97 | 74 | 118 | 2300 |

| T1-060-090 | 60 | 9000 | 14.5 | 74.5 | 54 | 99 | 74 | 120 | 3200 |

| T1-060-120 | 60 | 12000 | 14.5 | 74.5 | 54 | 99 | 74 | 120 | 4000 |

| T1-060-160 | 60 | 16000 | 15.5 | 75.5 | 60 | 100 | 80 | 120 | 5000 |

| T1-060-200 | 60 | 20000 | 15.5 | 75.5 | 60 | 100 | 80 | 120 | 5600 |

| T1-060-300 | 60 | 30000 | 18.5 | 78.5 | 64 | 104 | 83 | 122 | 6300 |

| T1-072-020 | 72 | 2000 | 9.75 | 81.75 | 47 | 108 | 68 | 128 | 2300 |

| T1-072-040 | 72 | 4000 | 11.25 | 83.25 | 45 | 100 | 66 | 120 | 2600 |

| T1-072-060 | 72 | 6000 | 12.75 | 84.75 | 47 | 108 | 68 | 128 | 3400 |

Industrial Man Lifts is your aerial access solution provider. We can customize any product for any size job. Operators always standing by, (727) 490-8839.